Discussing Substrates, Operations, and More; Interview with GreenLeaf Medical

15 March 2024

Interview with Samer Abilmona from GreenLeaf Medical

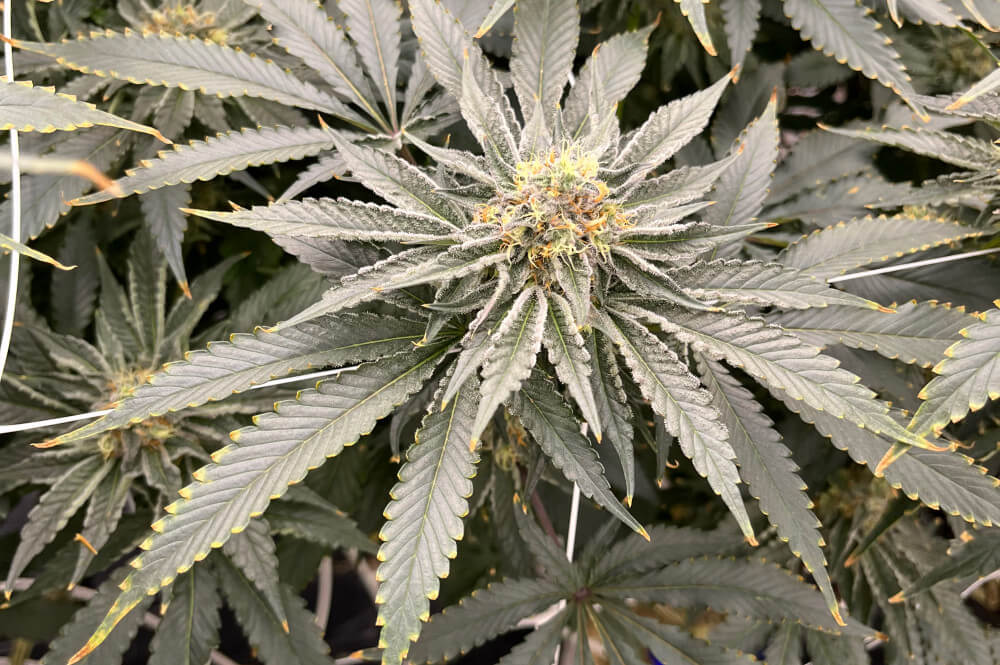

GreenLeaf Medical started in 2017 and has grown tremendously since then, growing and selling a full range of products to the medicinal market within the USA. Samer Abilmona has been in the cannabis industry for a little over 10 years, but he has cultivated cannabis for the majority of his adult life. He has been the Executive Director of Cultivation and Operation of GreenLeaf Medical since 2019, then the company consisted of one cultivation facility, started to work on the second, had one dispensary in Maryland, and recently received a license in Virginia. Nowadays, the company is a multi-state operator, with facilities in Virginia, Pennsylvania, and Maryland. The cultivation is tailored to their market leader, smokable flowers. Other products within their range are live resin, live rosin, and distillates for vape cartridges as well as for edibles. About 6 months ago GreenLeaf Medical merged with Columbia Care, now the Cannabist Company, Samer has been managing a few additional cultivation and extraction facilities in West Virginia, two facilities in Washington DC, and a second Virginia location.

Exploring the Efficiency of Stone Wool: Samer's Journey in Advanced Hydroponic Cultivation

“I worked with almost every growing medium that is available; deep-water culture, flood and drain beds, coco, cocopeat, hybrid soil, peat soil, living soil, no-till beds, and of course, stone wool” Samer shared. He stated that one of the very important things on a commercial scale is repeatability and consistency, being able to have predictable results in your harvest. “In the right system, stone wool is very predictable and consistent as far as your saturation rates, water requirements, and all these criteria. The smaller stone wool blocks, that can hold the same amount of root mass compared to bigger coco or soil containers, are also very beneficial for the company. From a hygienic and cleaning point of view, not having, for example, coco fiber all over the facility, makes it easy to transplant weekly more than a thousand plants from the vegetative to the flowering rooms. Also, the fact that we can automate allows us to rely on the team to focus more on plant work and environmental control, which will contribute to the yield and the quality of the buds.

Realizing Value and Efficiency

We asked Samer to share with us when was the moment he knew that Cultiwool stone wool was the best substrate for GreenLeaf Medical. He replied that what attracted him to the products of Cultiwool was that they were able to replicate the same successful results with a better product that reduced the costs for the company, which was very important as the company was on the way to a bigger scale. “Every penny matters in the cost of production. Being able to get reliable and consistent products with Cultiwool at a competitive price in the market was very important to the company.”

In the photo, Ryan Wankel (left) and Samer Abilmona (right) at GreenLeaf Medical

Stone Wool Quality & Its Importance

“We found with the Cultiwool brand stone wool that the received blocks are very reliable. It is noticeable that there are almost no imperfections and spots where the stone wool collapsed or had other quality issues such as soft or hard spots. When we measure our block saturation and runoff, we find a very consistent dry back and saturation from block to block. It is very important for us because, at such an operational scale, you cannot walk around feeling your blocks all day, you must be able to rely on the irrigation system to do its job, while the substrate has to maintain these saturation points throughout the cycle of the plant”.

Stone Wool Product Choice per Growing Stage

GreenLeaf Medical goes from 1.5 AO propagation plugs to 6x6x6 inch blocks (also known as cubes) in flowering. When Samer first arrived at the company, 4-inch blocks were placed on 6-inch blocks when the plants were put into flowering stage. Nowadays, they use 6-inch blocks from the start to the end of the growing cycle. “We made this change because we found the 6-inch block can hold the root mass and behave very predictably, allowing us to control the irrigation without having inconsistent dry back. This can often occur when stacking different sizes and densities of stone wool products on top of each other. Also, we have a quite quick ‘turn-around’ cycle, meaning, we are not overly vegging our plants, letting them get too large before they go to flowering. Therefore, we did not find the need to add additional blocks or slabs”.

EC and Water Content Steering per Growing Stage

“If you are crop steering and trying to tailor the irrigation based on the growing cycles, the more you can predict and have consistency in your substrate, the easier the steering will be. When you are no longer chasing wet or dry plants, nor are you trying to get the plants to a consistent point, you can then focus on the right water content (WC) and the right EC levels”, Samer explained and elaborated; “It is crucial to make sure the substrate sensor used is accurate and placed correctly. The steering is based on sensor reading, and as it is impossible to have a sensor in every single plant, the grower has to be able to trust that the results from the sensors placed in a few individual plants all over the cultivation area are representative of the state of the rest of the blocks in the facility. That is again circling to the importance of block consistency, without consistent block, for example, EC or pH fluctuation between blocks could occur, making it less reliable to steer based on one block's sensor results, raising the risk of missing specific targets along with environmental cues. In general, we always try to pull the right levers to achieve the best growth and maintain maximum metabolic activity in the plants as much as possible. We use substrate and environmental sensors to be on top of it”. Samer's approach is everything affects everything else, therefore they use their environmental control, irrigation, and substrate sensors, all to make sure the right EC and WC levels are maintained during the cultivation, “to make sure we get what we want from the plant, depending on the growing stage of the plants, we make the necessary changes to the EC and water content”.

Importance of Space & Storage

Samer mentioned that they use a lot of stone wool units per year, but from a storage perspective, they do not know where to keep them. “To be able to continue buying in bulk for the best pricing and to be able to maintain a steady supply, Cultiwool has been able to work with the requirements GreenLeaf Medical has from the storage perspective. We were able to buy from vendors containers at a time and work with them to store the stone wool for us on an ‘as-needed’ basis. That allows us to get the best pricing, the vendor to secure us as a client, and Cultiwool to secure an entire shipping container worth of a sale. Otherwise, we could not buy these volumes. All in all, it is a very cooperative dance we have going. This level of flexibility and working relationships is something we are looking for in all our providers, because of the scale we run at, we cannot allow a lack of product or delay. Therefore, it is extremely valuable to know that we have a steady and reliable supply, and even if we do run out, we know we can get an emergency shipment sent down. This communication is crucial to us, keeping the facility running smoothly with no change within the day-to-day operations”.

Get in touch

On this website you will find more information on the Cultiwool stone wool substrates and instructions for optimum use! If you have any questions, remarks, or requests, please feel free to contact us here, or via our Facebook, LinkedIn, and Instagram accounts.

More items

Where can I find Cultiwool?

Discover more about our Cultiwool network