Substrates side-by-side; How Do I Choose the Substrate Best Suited to my Situation?

5 February 2025

At Cultiwool, we are frequently approached by growers who want to do a side-by-side of the substrate they are using and Cultiwool. We are happy to facilitate these trials, even provide support on their success. However, there are some common improvements we see across the board that can raise the quality of the trials and improve your decision-making. Therefore, we have written this article to help set up the perfect substrate trial in a facility.

Setting Up a Trial

Before the trial starts, it is important to define the metrics/key performance indicators (KPI) when determining a substrates performance. The first metric that comes to mind might be flower yield per plant. While important, it is not the only driver for profit in your grow. Be conscious about all costs that go into growing a plant by looking at the total cost of production. Besides flower yield and price per unit, the substrate can influence plant growth rate (i.e., how quickly does the plant reach a certain height) and labor inputs. For example, the cross grooves on the bottom of the Cultiwool stone wool speed up the placement of the blocks in your facility. Cultiwool stone wool also has superior water holding capability, allowing growers to maintain proper water content in the block throughout the entire grow, reducing total nutrient and water inputs, directly saving on the bottom line operation costs.

Know your substrate

Scenario 1, Comparing Stone Wool to Stone Wool

The devil is in the details for the growers that compare Cultiwool to another stone wool brand. It is important to note that each stone wool brand requires its own irrigation strategy to maintain proper water distribution in the block. To unlock the full potential of Cultiwool technology, like the cross groove drains and donut rings, nuances need to be made to the number of irrigation shots and shot sizes. To allow for a true comparison on block performance, different brands would need to be irrigated in separately controlled irrigation zones. In the end, a proper trial will result in an unique and improved irrigation strategy for Cultiwool blocks. Our blocks have the signature donut ring that allow homogenous application of nutrient solution and the cross grooves improve drainage. This means more accurate crop steering for a better crop and an improved bottom line through optimized nutrient and water use.

Scenario 2, Comparing Stone Wool to Another Substrate

For growers who are experienced with using a substrate different than stone wool, the trial requires a different approach. First of all, we need to look at the set-up of the irrigation system; are pressure-compensated drippers installed? If so, what is their capacity in L/hour? An irrigation strategy will be less effective if the drippers are not properly spec’d or if the control system does not allow for frequent irrigation events.

Growers that are used to other substrates often have drippers with a capacity corresponding to a larger substrate volume. However, if the dripper capacity is too large, it might cause excessive channeling (click here to read more about channeling). The shot size must be controlled well to ensure a consistent and equal irrigation between blocks. So, we highly recommend using pressure compensated drippers with a capacity of 2 to 3 L/hour. The irrigation strategy in other substrates is also vastly different to stone wool. When growing in stone wool, it is recommended to give more, but smaller in size irrigation shots. We are happy to assist in developing a tailor made irrigation strategy for our products.

Growers operating a GACP-certified facility will find that growing in stone wool comes with additional benefits besides improved steerability (click here to read more about the benefits of stone wool). Stone wool is inert and the substrate holds its shape well. Meaning that less debris is found during the growing cycle, resulting in reduced pest pressure. All in all, Cultiwool stone wool can reduce labor inputs and put less pressure on the filtration system.

Data Driven Decision Making

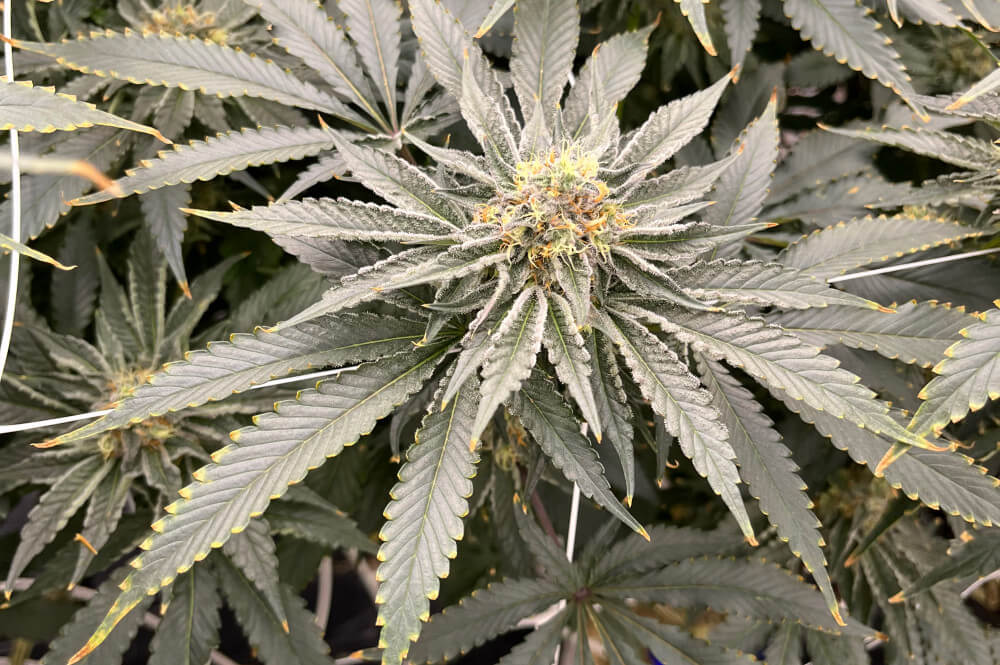

Data-driven decision-making is crucial when comparing different substrates. To achieve the best results, growers should monitor their plants above and below ground development. Irrigation is preferably monitored using soil moisture sensors, as these measure root zone conditions in real time. Alternatively, a scale can be used to weigh blocks to track water use. Real-time monitoring allows growers to adjust the amount of water and fertilizer accurately. Growers can also perform visual inspections of the roots growing around the edges of the block. For example, how long does it take for the first roots to appear, what colour are they, and are fine root hairs present?

Regarding above ground effects, growers can monitor vegetative and flowering stage growth by checking plant height, internodal distance, and leaf and flower development. Of course, after the harvest, the weights can be compared. Preferably, growers have collected data over multiple runs, giving them a reliable average performance. This helps to compare performance during different seasons for example.

It is also important to collect relative data in regards to determining the KPI’s. More times than not a grower gets stuck collecting data that is relatively useless when actually comparing data at the end of a trial or not looking at the larger picture of production. Decisions should be data-driven so make sure to collect only useful data and as mentioned in the paragraph previously, the total cost of production.

All in all, Cultiwool supports growers in setting up effective side-by-side substrate trials to compare their current substrate with Cultiwool products, emphasizing data-driven decision-making for optimal results. While flower yield per plant is a key metric, other factors like water and nutrient use, plant growth rate, rootzone management, and labor inputs should not be overlooked. Cultiwool stone wool offers unique features like cross grooves and donut rings for better irrigation and drainage. Click here and reach out to us to set up a trial tailor made to your facility!

More items

Where can I find Cultiwool?

Discover more about our Cultiwool network