Vegetative and Flowering Stages of Cannabis on Stone Wool

13 October 2022

What Has to be Taken Into Account for Successful Cultivation?

Do you know what has to be taken in account for succesful cultivation? In this knowledge article we will tell you everything you need to know from the end of the propagation stage to the vegetative and flowering stages in cannabis cultivation.

When the propagation stage is reaching its end, the Starter Plug cannot support anymore the advanced growth and development of the cannabis plants. That is the moment to move on to the next step, which is the vegetative stage. Usually, the plants in the Starter Plugs will be then transplanted into another stone wool product.

The best fit

The most popular Cultiwool product growers use for the vegetative and flowering stages in cannabis cultivation is the 6x6x6 Block (15x15x14.2 cm). Nevertheless, Cultiwool offers several different products, which growers can choose from, in order to have the best fit for their facility, growing method, and cultivar. For more information about the individual characteristics of our products, please check this article.

Critical aspects

Depending on the grown cultivar, it is important to determine what is the best density to place the crops at, and how to irrigate them (e.g., if using a dripping system, how many drippers does one plant need?). Once aspects like that were decided on, the plants can be put into the cube or slab the grower chooses. Substrate volume is critical in regard to the irrigation strategy you can apply. The higher the substrate volume the slower the change in WC/EC will be, the lower the volume the quicker you can change the WC/EC in the root zone. Too small substrate volume will also lead to many irrigation sessions in order to keep the water content stable. Therefore decisions in product choice are crucial for success, and that is where you could use the support of our experts; please get in touch with us and we could assist you.

The vegetative phase

Next, when the conditions are preferable, the cannabis plants will expand their root system and establish it through the stone wool, thus, the vegetative stage. The plants will be growing and so the fresh weight of the crops will increase. The length of the vegetative period is mostly depending on the climate conditions the plants are provided with, but also on the cultivar. On average, this stage lasts 2 weeks, but can also take from only a few days to 28 days. During this period, it is important to maintain healthy crops by, for example, keeping their sink-source ratio balanced (crop handling activities such as leaf removal).

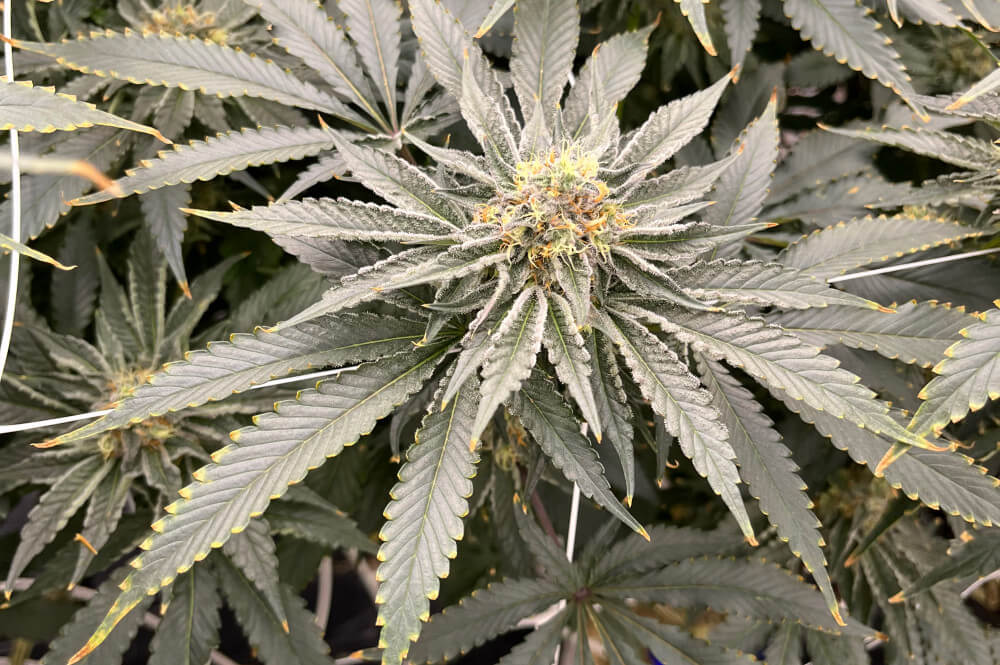

The flowering phase

Once the vegetative growing stage is finished, the plants should be entering their final stage, better known as the flowering phase of cannabis. This is when you go to short days of 12 hours of light so the plants will start to develop flowers. At this point many changes in the operation should take place; e.g., changing the climate conditions (e.g., lower RH levels and higher VPD, shorter light period, higher light levels, higher CO2 levels, etc.), as well as the irrigation schedule and fertilization recipe (e.g., lower WC in the root zone, and change in the K:Ca ratio, respectively). Once all required changes are made, this stage can last from 8 to 10 weeks.

At the end of this step, the cannabis plants will have their flowers ready to be harvested. At this moment the cultivation part is completed, but not the production. Next, the harvested flowers will go into the varying post-harvest stages, with the goal of having at the end healthy, clean, safe, and effective products for patients and other clients.

Want to know more?

On this website you will find more information on our stone wool substrates and instructions for optimum use! If you have any question, remark, or request, please feel free to contact us here, or via our Facebook and Instagram accounts.

More items

Where can I find Cultiwool?

Discover more about our Cultiwool network