The Influence of Higher Light Levels on the Irrigation Strategy for Cannabis Cultivation

17 February 2023

An interview with Ryan Wankel

Cannabis is known to be a highly demanding crop, but what does it mean for growers' irrigation and lighting strategies? We wanted to know how does high light strategy influence the irrigation strategy for cannabis cultivation on stone wool? Therefore, for this article, we interviewed Ryan Wankel, our technical sales manager for North America.

Before joining the team of Cultiwool, Ryan, a second-generation cannabis grower and a multiple times winner of the Cannabis Cub Award, has worked for 7 years in a lighting company Heliospectra, and has a lot of experience and knowledge regarding that (to learn more about Ryan please check this webpage).

"It is a very symbiotic system where one thing will directly have an effect, positive or negative, on many others" Ryan started explaining why changing the light is not only effecting the irrigation.

What happens when increasing light levels

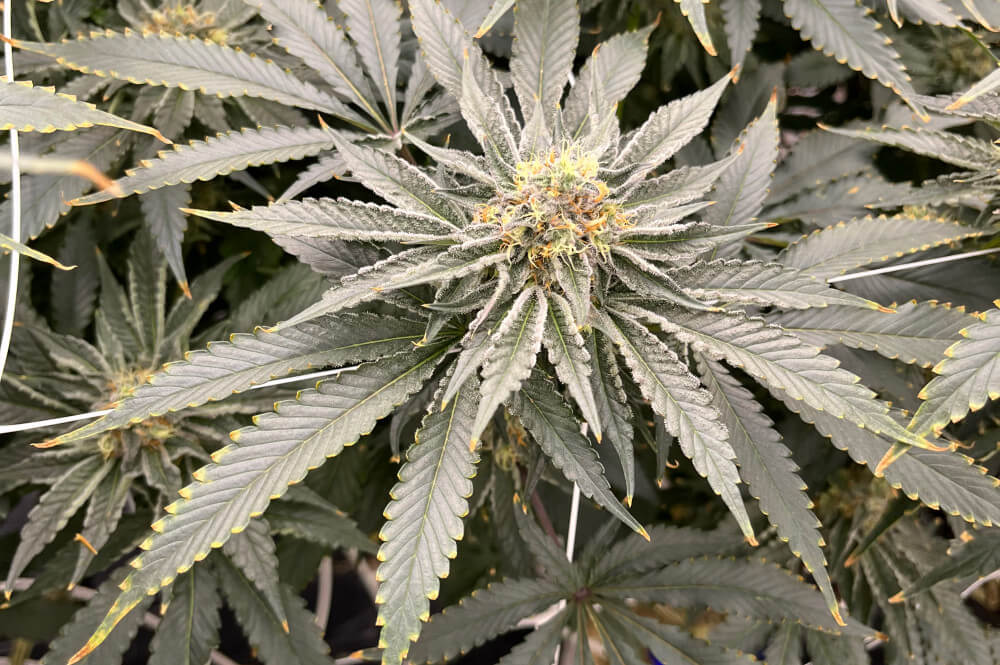

It is important to understand the consequences resulting from increasing the light levels; "In general, increased light levels are going to increase the demand from the plant. That is going to open up the stomata even more, which is going to increase your transpiration. And anytime you are increasing the transpiration levels, you must look at your irrigation schedule and make sure it is working hand in hand with those increased light levels."

It is true that cannabis needs more light and therefore water and nutrients than many other crops. Nevertheless, not all cannabis cultivars will need the same (high) light level. "When a grower wants 1000 micromoles, I say sure, but if a grower wants 1200 or 1300 micromoles, I ask why." Some growers increase the light they provide the plants with to increase their yields. However, Ryan has mentioned an interesting point; "yield and quality do not necessarily work hand in hand"; more light will create more biomass, but will it be allocated to the flowers, and will it increase quality? There is no guarantee of that.

Keeping in mind

A point often forgotten by cannabis growers is the understanding of what market they are producing, or what is their final product. A company has to understand and have a clear business (and based on it) and cultivation plans. Knowing what makes sense to your business (e.g., higher quality and lower yield, lower quality and higher yield, or their balance), should have a big say in the decision of which light strategy to apply. And as such, knowing your cultivar, its growing demands, and your business approach, will give you the answer that is right for you; should you go above the 1000 micromoles, or not.

Another thing to keep in mind, is the growing stage you are in; are your plants in the vegetative or flowering stage? A lot of that has to do with the photoperiod of your plant, going from that vegetative cycle to a generative one; 12 hours of light. Not only the growers are making a photoperiod switch, but they are often also making a lighting adjustment; so usually going from a blue light environment, which promotes leaf growth, and can stimulate root production, to then shifting to a more red spectrum, and that causes natural reactions within that plant. Where red light does promote flower growth, and stem elongation which can also stimulate roots as well. Ryan also mentioned “I always remind growers that every irrigation session has a vegetative effect on the crop”. That plays a role when a grower is using growing manipulations, for example, dry-backs closer to the end of the cultivation cycle. Also, a grower must ensure that their irrigation strategy allows transpiration before irrigation. Meaning, a grower has to decide on the right time to start irrigation every day, allowing first the crops to transpire.

The right environment

Furthermore, also a crucial aspect to remember is that the more light that you give a plant, you have to make sure that your environment can start to handle that as well; Is there enough CO2? When pushing the plant to its upper limits and threshold, your margin of error becomes much smaller. Meaning, a grower will have a higher risk to handle. In case something goes wrong with a piece of equipment, which is reasonable when working with people, technology, and machinery. Then, the timeframe to change/fix that error before it will affect your crops, quality, and/or yield, is smaller. So those growers will have to make sure they have the right knowledge, automation, and sensors. Therefore, often when growing in a high-demand environment growers will tend to provide smaller shots of irrigation with a higher frequency.

The difference between LED and HPS

"Growers have to understand that not all light is created equal. Looking at light levels; 1000 micromoles from an HPS is different than 1000 micromoles produced by LEDs". Ryan led the discussion to a slightly different point. "HPS naturally increases evaporation rates of water by increasing the temperature, just because it has such a high amount of infrared within the lamp. In a LED environment, since you have that lack of infrared, you need to make sure that it's done with your environment, just your ambient temperature. Of course, the spectrum of the LEDs is important and can be changed/adapted depending on the growers' desires, which is another advantage LEDs have over HPS."

Knowing that, we had to ask; Do you see a need for EC adaptation with increased light and/or change from HPS to LED-based cultivation? Ryan did not hesitate; "100%. Increasing light levels tend to create an increase in the demand plant. I would say that works hand in hand with increasing the EC. That is because the more efficient and usable your lights are for the plants, the higher the demand for nutrients will be." According to Ryan, a general rule of thumb when switching from HPS to LEDs is to increase the EC levels by at least 0.2 mS/cm.

A safe approach

All in all, generally and according to Ryan, for high production cannabis facilities, a light strategy of 1000 micromoles and irrigating more often and with smaller gifts, will be a safe approach. Nevertheless, the company has to know and take into consideration its business goal, cultivar grown, and growing stage, and maintain the right balanced environment (e.g., a high-demand environment will require more CO2, etc.). Starting with an inert and consistent substrate like stone wool, a grower knows that he/she is providing a clean, safe, and reliable foundation that just has to be controlled and adjusted according to the plants' needs, regardless of the changes done in the light and therefore irrigation strategies.

Want to know more?

On this website you will find more information on our stone wool substrates and instructions for optimum use! If you have any question, remark, or request, please feel free to contact us here, or via our Facebook and Instagram accounts.

More items

Where can I find Cultiwool?

Discover more about our Cultiwool network