What is Slag Wool and How does it Differ from High-Quality Horticultural Stone Wool?

30 May 2023

As more and more products and companies become available on the market, it is always important to do a little research. Not only on the company itself but how the products are being produced. A little bit of research and asking the right questions can save money and time, but maybe the most important, the crop and your investment.

Stone wool vs. slag wool

Stone wool, also known as rock wool, is no different. For all purposes in this article, we will refer to it as stone wool. Not all stone wool is created equal and there are several contributing factors as to why. One of the most common which we will focus on in this article is the differences between high-quality stone wool (mineral wool) versus slag wool.

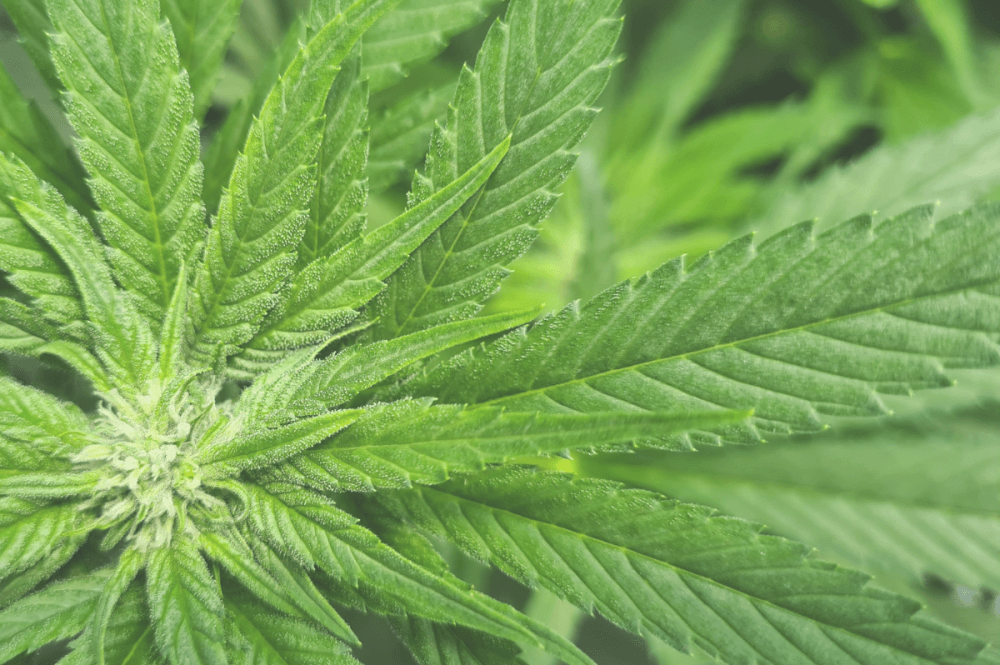

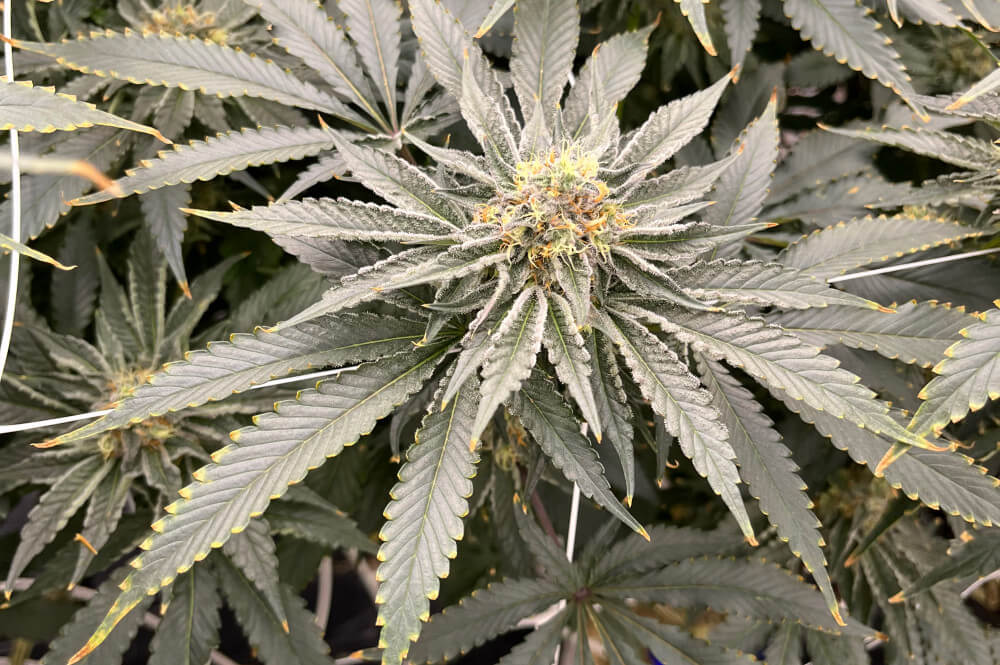

Both of these products are quite common in the horticultural space but growers should better understand what each is, production methods, and how this can affect your cannabis operation.

How stone wool is made

First off let’s start to understand what exactly is high-quality stone wool or rather what makes a high-quality stone wool. Stone wool consists of volcanic rock, typically basalt. Stone wool is a furnace product of molten rock at a temperature of about 1600°C, through which a stream of air or steam is blown. More advanced production techniques are based on spinning molten rock in high-speed spinning heads somewhat like the process used to produce cotton candy (Connor, 2022). It was first thought that stone wool was discovered when a strong wind would blow molten hot lava in this fine wool-like fiber (Crane & McLaren, 2008). For more information about stone wool, you can read our article by clicking here.

The 'dirty' secret of slag wool

Slag wool is produced in a similar fashion but is using a different material in order to create fine fibers. Slag wool is made from blast furnace slag, a waste byproduct of steel production. The industry estimates that over 90 percent of the slag used for insulation is purchased directly from steel manufacturers. The remaining 10 percent is mined from waste disposal sites and landfills.

Therefore, a large concern for growers, when understanding the differences of high-quality stone wool vs slag wool, is the possibility of heavy metal contamination utilizing a slag wool material. With more and more strict measures being placed on heavy metals and cannabis products, growers must minimize all possible risks of contamination. The most common use for both materials is for building and home insulation as well as soundproofing. Both products are very fire resistant and can be formed to any specifications regarding air space, shape, etc. Both high-quality stone wool and slag wool are hydrophobic materials that do not break down due to excessive moisture. All of these properties can be controlled in the manufacturing process and tailored for other specific applications like horticulture.

The importance of homogenity

You may ask yourself why this matters, but this is where the inconsistencies and imperfections can come from. In horticultural stone wool, especially for propagation, where we work with sensitive materials like cuttings, seeds, or tissue cultures, the homogeneity of the product is by far the most important criterion. High homogeneity will provide equal start conditions for the different plants growing on separate stone wool plugs or blocks. Therefore, the difference between excellent and lousy stone wool is its homogeneity. A homogeneous stone wool can be created and monitored only by high-tech machinery, an experienced team, and high-quality starting material. This is the exact reason why not every stone wool-producing company can be making stone wool for horticulture purposes. This is where the consistency of the product can vary greatly from manufacturer to manufacturer. Also, as mentioned previously, stone wool and slag wool are both hydrophobic materials. This means that a wetting agent must be applied in order for the block to maintain its near perfect water-to-air-ratio.

As I am sure you are already aware, not all wetting agents are created equal. Lower-quality wetting agents can lose effectiveness over time reducing the blocks’ water retention capacity. This also brings up the importance of how this wetting agent has been applied to the fibers. Naturally, the wetting agent is pulled down through gravity but how it is applied can minimize this and reduce the chance of channeling. In more simple words, the wetting agent is especially important at the first initial saturation of the stone wool products. After that, the quality of the substrate with a combination of the applied irrigation strategy is important for the water retention capacity of the stone wool.

About horticultural stone wool

Being that the primary purpose of stone wool is insulation, many manufacturers have to change their production lines to accommodate the production of horticultural-grade products. These machine lines can be set up temporarily which can cause inconsistencies during each production run. Meaning, not every line is producing stone wool for horticulture for 100% of their operation time. Batches can vary quite greatly from batch to batch. This can determine the quality of the product. High-quality horticultural wools are produced on factory lines specifically for this application. This creates a more homogenous and consistent product often noticed by Cultiwool cultivators.

A consistent product can allow the grower to optimize efficient watering and nutrient use, minimalize channeling and create an ideal root zone environment. This leads to more consistent crop steering techniques and efficient dry backs to influence and drive quality. Through the use of sensors, growers can control these features knowing they are working with a consistent product allowing for more precise control. Cultiwool is changing the standard of quality and consistency when it comes to stone wool and cultivations are noticing. Cultiwool is the RHP-certified substrate (to find out more about RHP check out our 'about us' page) that upholds the strictest standards when it comes to high-quality horticultural materials.

Want to know more?

On this website you will find more information on our stone wool substrates and instructions for optimum use! If you have any question, remark, or request, please feel free to contact us here, or via our Facebook and Instagram accounts.

References

- Connor N., (2022). What is Stone Wool – Rock Wool – Definition. https://www.thermal-engineering.org/.09/05/2023.

- Crane A. E. & McLaren L. (2008). Insulation Materials: Rock and Slag Wool Insulation: A Sustainable Choice. https://insulation.org/io. 09/05/2023.

More items

Where can I find Cultiwool?

Discover more about our Cultiwool network