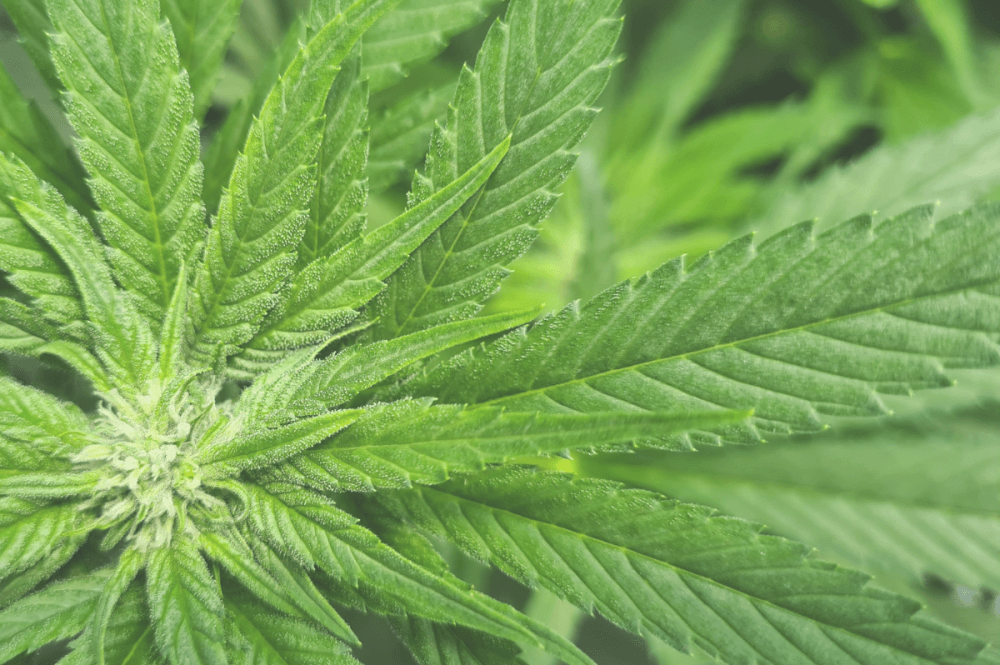

The Effect of pH Levels on Cannabis Cultivation; What Should it Be?

17 November 2022

Previous articles discussed aspects such as the importance of a correct irrigation scheme, daily dynamics in the stone wool, EC levels monitoring and adjustments, and more. Yet, there is one more important point to discuss, and it is the pH level.

What is pH and how does it influence cannabis cultivation?

pH is a quantitative measure of the acidity or basicity (alkaline) of a liquid solution. Ranging from 0, for an acidic solution, to 7 for a neutral solution, up to 14, which defines an alkaline solution. When talking about pH levels in cannabis cultivation, similarly to the EC, attention should be given to the pH of the irrigation solution, but also the drain water, and root zone pH.

The relationship between nutrient absorption and uptake by the plants and the pH levels of the solution and in the root zone is extremely tight and dependent. For example, even when all required nutrients are supplied to the crops through the irrigation system, the plants can still suffer from nutrient deficiency, and adding more nutrients might not be the solution, but adjusting the pH levels. At is can be seen in the Figure below, the pH levels determine the availability of nutrients for plant update. In other words, when the pH is not within the preferred range, plants cannot update nutrients even if they are right there. Therefore, the pH of the nutrient solution should be kept around 5.5 to 5.8, as it is a pH range that allows balanced nutrient uptake by the plant.

![22088 b cultiwool phnutrientavailability 1080px[1] 22088 b cultiwool phnutrientavailability 1080px[1]](https://www.cultiwool-substrate.com/cache/4ddd67d6afc9e2f8f3f3d203cb35f79b/22088_b_cultiwool_phnutrientavailability_1080px[1].png)

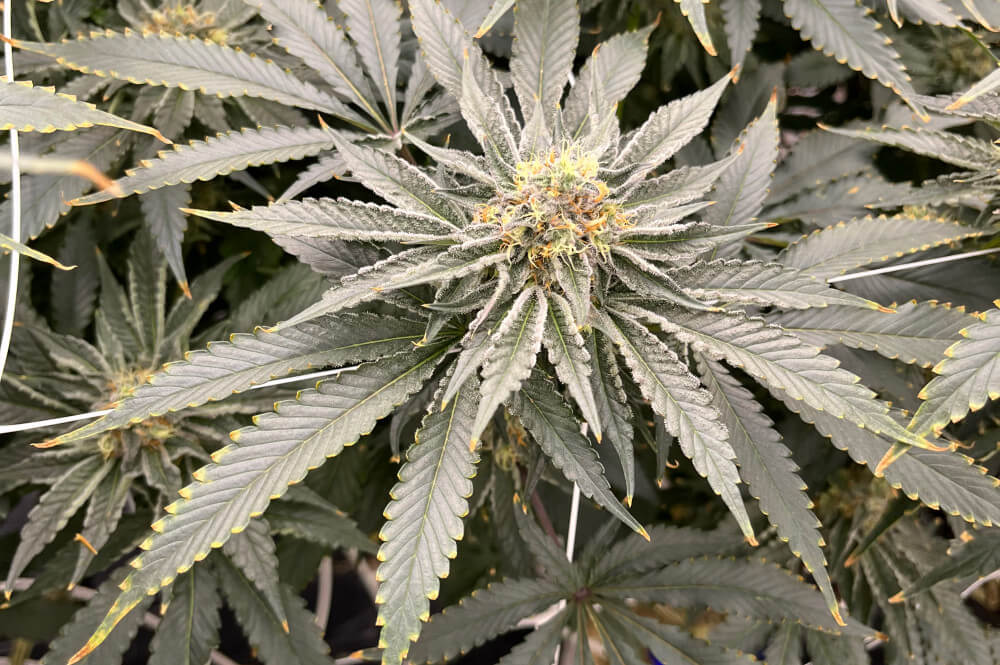

What happens and what should be done when the pH levels are not within the desired range?

Too low pH levels

There are several reasons that might explain having too low pH levels, for instance, the irrigation setting pH is set below 5.3, and the fertilization recipe composition is not favourable (e.g., too much ammonium phosphate or ammonium nitrate). It is also possible that that plant is too generative, and perhaps others.

When taking action to correct the pH of a root zone, it is possible to increase the setting of the pH irrigation scheme to 6.0. When changing the fertilization recipe the NH4+ amount can be decreased. Also possible to decrease the length but increase the frequency of the irrigation gifts. Lastly, steer the crop to a more balanced state; when too generative, one would need to steer towards the vegetative direction. That can be done by reducing the number of buds, flowers, or fruits (depending on the crop).

Furthermore, there is another risk worth mentioning, which occurs when the irrigation solution pH is reduced below 4.5. This acidic solution creates a risk of breaking down the stone wool's fibers, which can result in a collapsing of the used stone wool product.

Too high pH levels

When dealing with too high pH levels, most of the described above can be expected to be the opposite; therefore, possible that the irrigation setting pH is set either high (above 6), or that the plants are not balanced and too vegetative. To tackle that there are several possible actions. First, making sure that the pH for the irrigation setting is decreased. Next the NH4+ amount in the fertilization recipe can be increased and the rest of the recipe adjusted accordingly of course (e.g., increase Fe3+, etc.). Concerning the irrigation gifts, these should be reduced in frequency but increased in length. Finally, it is important that crops are balanced for best results, therefore, steering towards more generative plants could help (e.g., deleaf, maintain more buds/flowers/fruits, etc.).

Finally, when measuring the pH of the root zone, it should be within the range of 5.5 to 6.5. When it is above or below that, corrections should be implemented. Usually, that is done by adjusting the nutrient recipe given with the irrigation system. Please check this article for more information about how to measure and have constant control over the pH. All in all, of course during the cultivation the root zone pH will fluctuate. That is why monitoring the pH levels and adjusting when needed is crucial to maintaining healthy crops and high-quality yield.

Want to know more?

On this website you will find more information on our stone wool substrates and instructions for optimum use! If you have any question, remark, or request, please feel free to contact us here, or via our Facebook and Instagram accounts.

More items

Where can I find Cultiwool?

Discover more about our Cultiwool network