.png)

Stone wool: Unique Product Features of Our Blocks

5 oktober 2022

Tailor made quality

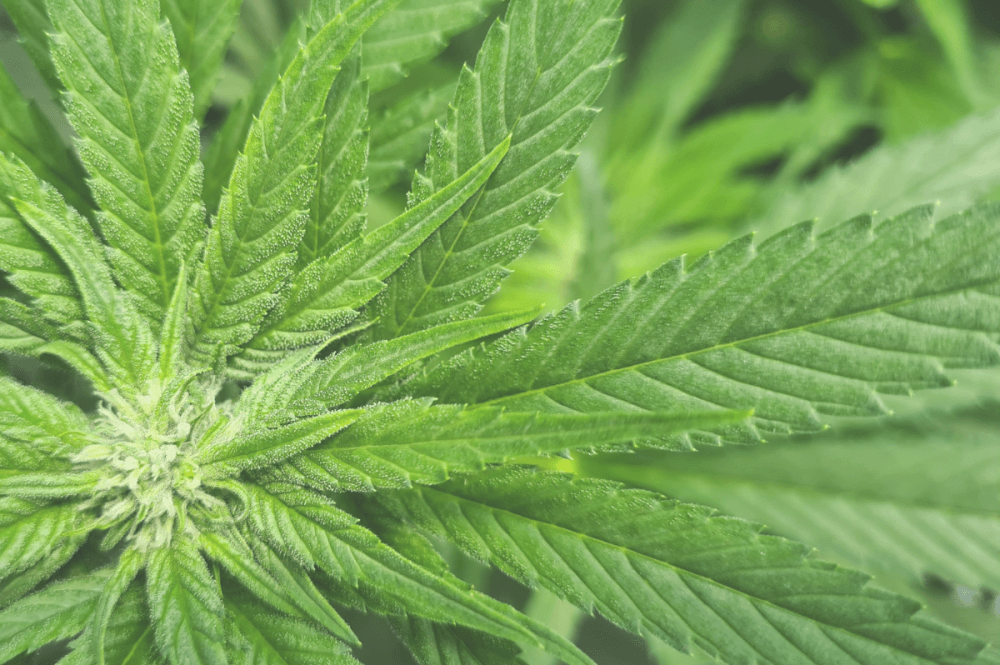

There are many aspects affecting the decision of which substrate to use, among these crop types and cultivation stages. Similarly to the way soil mixtures can be amended and customized, so are stone wool products tailor-made for the cultivation of a specific variety of crops. Stone wool can be manufactured in such a way that the density and orientation of the molten rock fibers determine the moisture holding capacity, air-filled porosity, and moisture gradient within the blocks.

About the benefits

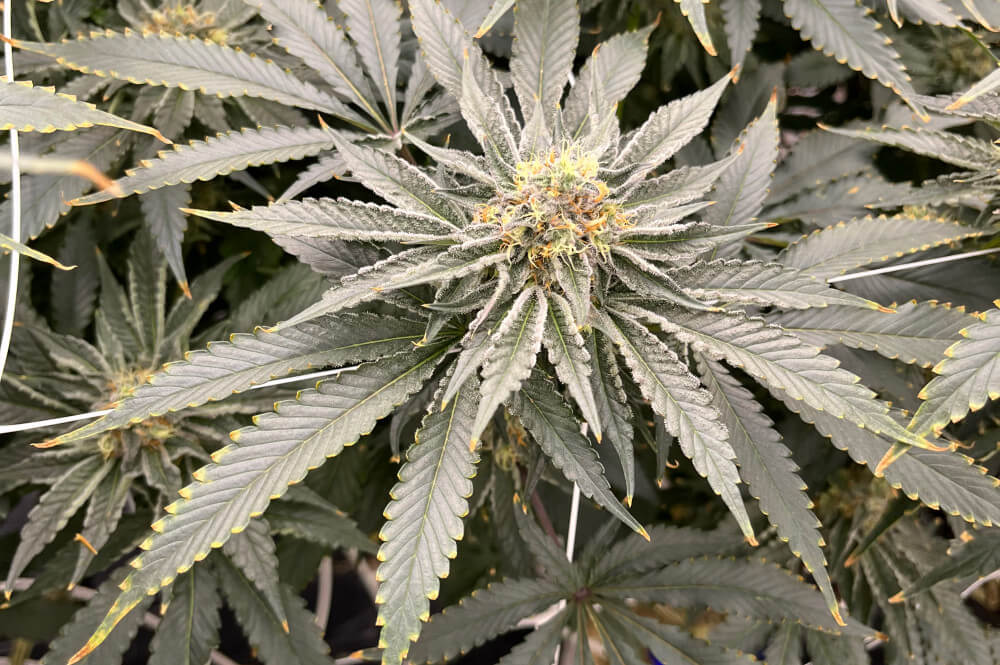

Overall, there are many advantages to using stone wool for many different crops. At Cultiwool we have engineered our products (plugs, blocks - cubes, and slabs) in such a way to fit the cultivation requirement of cannabis. It is important, especially because of the unique aspects of cannabis production; uniformity and hygiene. Whether it is because of genetic instability or varying conditions of growth, uniformity is a key to success and increasing yields for all growing stages, from propagation, to vegetative stage, flowering and harvest. Maintaining a hygienic environment in the cultivation facility is crucial to avoid crop and yield loss. The requirements are high for the quality control and certifications of cannabis production facilities, such as GACP in cultivation and GMP in post harvest. The different products offered by Cultiwool will allow the grower to have accurate, uniform, clean, and more sustainable irrigation and fertilization. These benefits will contribute to the health and balance of the root zone, will play a role in steering towards the vegetative stage or flowering, and generally optimize plant growth and development depending on the used cultivation and irrigation strategies. For more information about the story and benefits of stone wool check this article.

At Cultiwool we have worked to improve the products in order to adjust it to the needs of cannabis by using innovative and patented solutions in order to tackle some basic daily challenges cannabis growers might deal with. Introducing the Donut ring and Cross groove technologies.

.png)

Efficient water distribution

After initial saturation of the stone wool blocks, it is essential to maintain water distribution even throughout the block to promote healthy and vigorous root growth. Originally one dripper per block was considered the standard, and this evolved into two drippers on opposite sides. However, inconsistencies in root growth were still observed as a result of uneven distribution of water. In order to prevent this and ease cultivation, we developed the Donut ring Cultiwool stone wool; blocks that were engineered with a ring on the upper side of the blocks. At the moment of irrigation, these are filled up, allowing similar rates of nutrient solution to drip into the stone wool bocks. This method of irrigation allows for uniform and efficient distribution and use of water and fertilizers, which result positively affect plant growth.

![cultiwool6x6x6[3] cultiwool6x6x6[3]](https://www.cultiwool-substrate.com/cache/65a63e7b98e67b002a854cf43e697440/cultiwool6x6x6[3].png)

However, not only the method of irrigation determines water distribution within the blocks. Monitoring the drain has a heavy impact on the health of the root zone, for example, the EC levels. Standard stone wool blocks have a single groove on the bottom through which water can drain out. However, these have to be placed correctly on gutters to allow for them to function as intended. The risk of human error is always present, the cross groove technology of Cultiwool solves this. The cross groove pattern allows for uniform drainage of water from the stone wool blocks, irrespective of orientation, thus promoting regular growth, yield, and flower quality throughout your crop.

The team members of Cultiwool are in constant and direct relationships with the worldwide cannabis industry (suppliers, growers, etc.), as we aim to keep improving our products while contributing to the growers and developing the industry to manage challenges and find solutions for them in innovative ways.

Want to know more?

On this website you will find more information on our stone wool substrates and instructions for optimum use! If you have any question, remark, or request, please feel free to contact us here, or via our Facebook and Instagram accounts.

Więcej pozycji